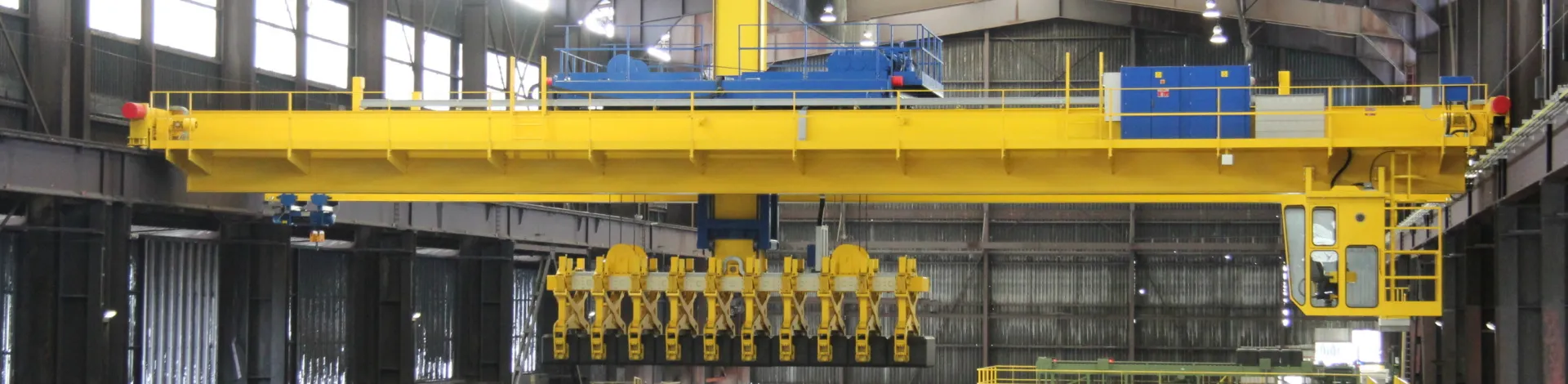

This crane is part of a 24/7 baking furnace process. To avoid disruption of this process, commissioning and testing activities were carried out during scheduled shutdowns.

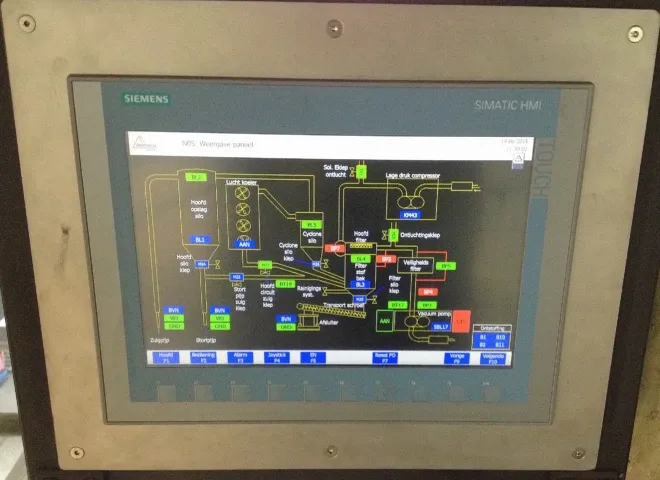

For the automation and electrical engineering disciplines, the scope of work included, among others, the following activities:

-

Reading out the existing software and converting it to Siemens TIA Portal

-

Programming and testing the new Siemens PLC

-

Replacing the PLC and frequency drives

-

Testing

-

Commissioning of the new control system

Delmeco’s responsibility within this project was the modification, implementation, testing and successful delivery of the new crane control system.

Client:

Century Aluminum is a producer of primary aluminium. The company operates facilities in the United States, Iceland and the Netherlands and employs more than 1,500 people worldwide. One of the products manufactured by Century in the Netherlands is anodes. Anodes are carbon blocks used as current conductors in the electrolysis process for aluminium production.