Delmeco distinguishes itself through high quality and precision. We integrate high standards into our engineering processes, resulting in reliable systems with a long service life.

Innovation within this area of expertise is essential. New systems are more efficient, faster and offer higher availability. By investing in modern technologies and process optimisation, we ensure that our solutions not only meet today’s requirements but are also prepared for the challenges of tomorrow. In this way, we continue to lead in an industry that never stands still.

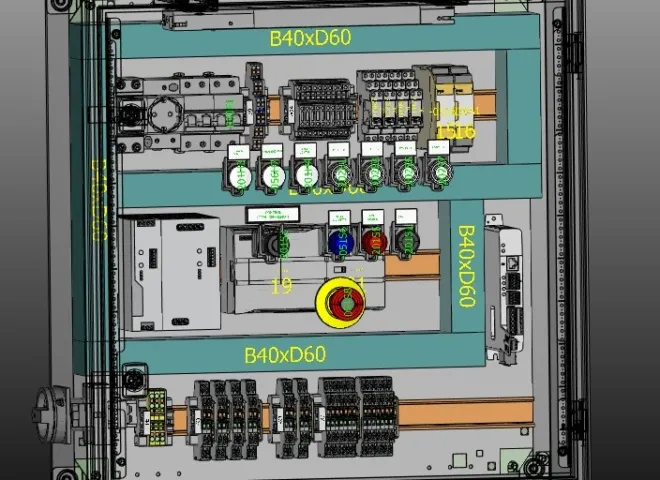

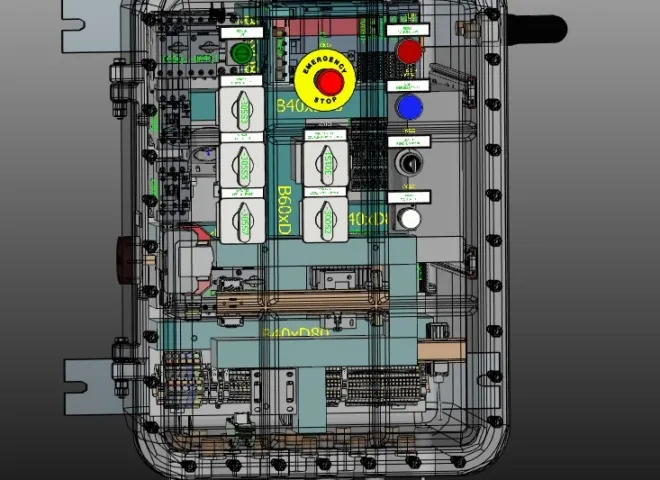

In the engineering of control panels, we use EPLAN, a specialised engineering platform for electrical engineering, automation and mechatronics. The design is developed not only into clear electrical schematics, but also into a fully configured 3D model of the physical control panel (digital twin). This allows you, as the client, to retain control over the project, while we provide expert guidance and carefully incorporate your requirements into the design.

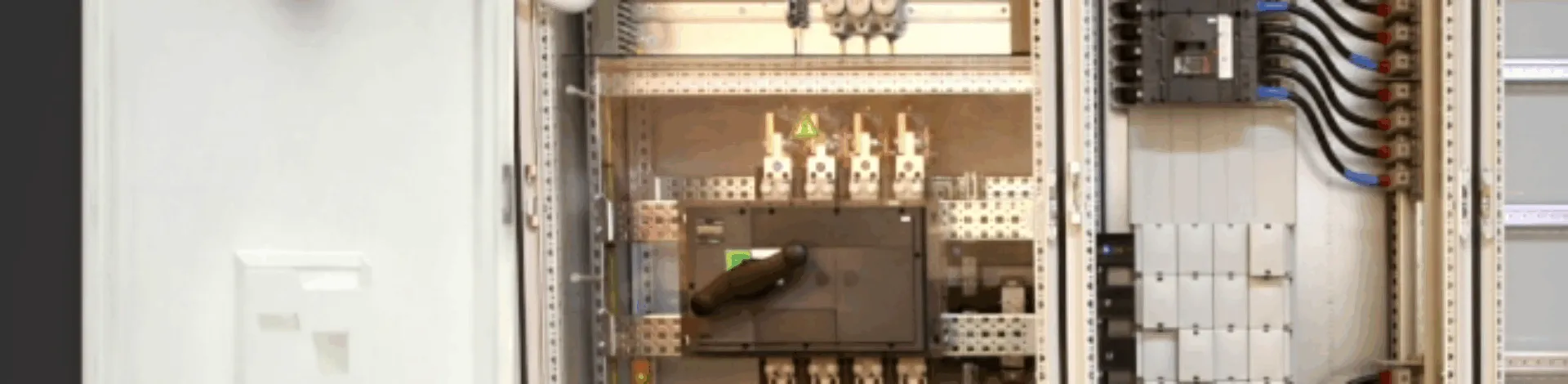

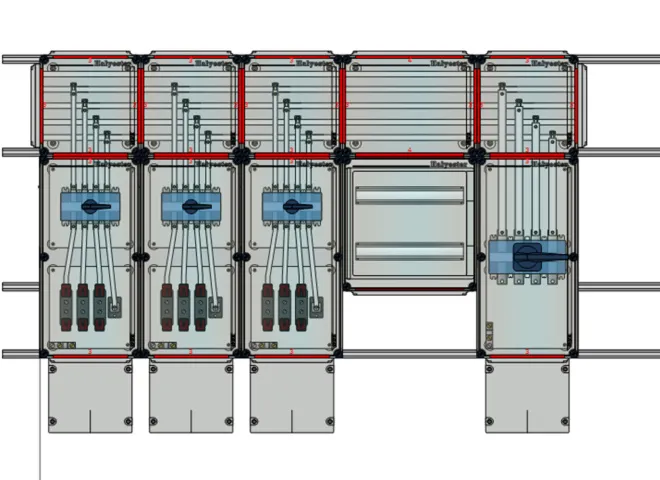

Due to the strict requirements of various power distribution systems, a supplier-provided configurator – such as the Eaton xEnergy Configurator – may form the basis of the design. By importing this configuration into EPLAN, the manufacturer’s specifications and guidelines are automatically ensured.

Throughout the engineering process, we ensure that control panels comply with all applicable standards and guidelines. These include standards such as NEN-EN-IEC 61439 (Low-voltage switchgear and controlgear assemblies) and NEN-EN-IEC 60204 (Safety of machinery – Electrical equipment of machines), as well as more specific standards such as NEN-EN-IEC 60079 (Explosive atmospheres – electrical installations). In this way, we guarantee quality, safety and compliance.

We engineer control panels for a wide range of applications. Some examples of projects we have delivered include:

- Sub-distribution board (425 A) in a Halyester application for supplying two PV inverters, including a connection box for surge protection and an energy meter, in a confectionery factory

- Sub-distribution board (160 A) for supplying various machines in a packaging department, with energy monitoring on the outgoing feeders

- Control panel for operating a hydraulically actuated bunker door in the nuclear sector

- Control panel for testing “water hammer” effects on plastic couplings

- Control panel for a loading crane in an ATEX environment

- Control panel for controlling conveyor systems in a fertiliser factory

- Control panel in a radiation-shielded enclosure, designed for use in an area with nuclear radiation to protect the equipment

- Operating panel (Hygienic Design) for a pasteuriser in the apple sauce line of a canned food manufacturer

- Operating panel with a Human Machine Interface (HMI) and control buttons for the main functions of a maintenance platform on the Zeelandbrug.