Onze inspecteurs onderscheiden zich door een werkwijze waarbij niet alleen een veilige en goed functionerende waterleidinginstallatie centraal staat, maar ook het minimaliseren van beheersmaatregelen en exploitatiekosten.

De opdrachten bestonden voor de vakdiscipline HVAC volgens BRL6010 uit:

-

Installatie-inspecties op basis van de Waterwerkbladen, NEN 1006 en de actuele versies van ISSO 55.1 en 55.2

-

Opname ter plaatse

-

Diverse temperatuurmetingen en tijdsregistraties ter plaatse

-

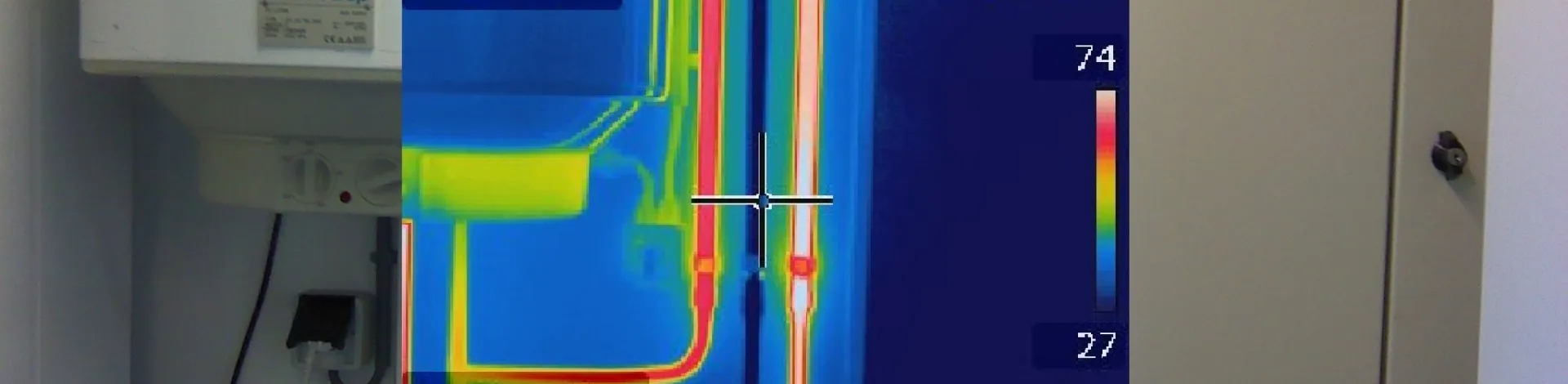

Fotoregistratie met een thermografische camera op moeilijk bereikbare plaatsen of ingestorte leidingen

-

Het in kaart brengen van de bestaande installaties

-

Het, indien van toepassing, opstellen van een aandachtspuntenlijst en werkomschrijving na overleg met de opdrachtgever

Aan de hand van deze werkomschrijving kan de eigen onderhoudsdienst van de opdrachtgever of een installateur de vereiste en/of geadviseerde installatieaanpassingen uitvoeren. Na afronding van de werkzaamheden door de onderhoudsdienst of installateur worden de installaties opnieuw geïnspecteerd. Op basis van deze inspectie worden de in ISSO 55 gevraagde risicoanalyses en risicobeheersplannen opgesteld, inclusief de bijbehorende tekeningen en schema’s.

Alle bovengenoemde werkzaamheden worden uitgevoerd door onze eigen gecertificeerde legionellapreventieadviseurs, conform de actuele BRL 6010-richtlijn.

Delmeco Raadgevend Ingenieursbureau is gecertificeerd conform BRL 6010 en daarmee bevoegd zowel niet-prioritaire als prioritaire installaties te inspecteren en de bijbehorende documenten op te stellen.

De verantwoordelijkheid van Delmeco binnen deze projecten omvat het inspecteren, begeleiden van de benodigde installatieaanpassingen en het opleveren van beheersplannen met bijbehorende risicoanalyses, schema’s en tekeningen. Deze werkzaamheden worden uitgevoerd conform de actuele eisen uit ISSO 55.1 en 55.2 en de geldende bepalingen in de Drinkwaterwet en het Drinkwaterbesluit.

Voor meer informatie over BRL 6010, legionellapreventie, inspecties en de wettelijke kaders van de Drinkwaterwet en het Drinkwaterbesluit kunt u hier terecht.

Opdrachtgever: diverse opdrachtgevers

Voor diverse opdrachtgevers zoals diverse gemeentes, Koninklijke Schelde Groep, Damen Schelde Naval Shipbuilding, Amels, Technico Installatietechniek, Orionis Walcheren maar ook voor zorgcomplexen, B&B’s, campings, jachthavens en verschillende andere bedrijfspanden hebben we legionella inspecties uitgevoerd.